World Creativity and Innovation Day has never been more relevant. Earlier this year, scientists issued a ‘final warning’ that serious action must be taken to reduce carbon emissions. Yet despite its net zero pledges, the UK government currently expects demand for electricity to increase by up to 60% by 2035.

Meeting such demand while radically reducing carbon emissions can only be achieved by applying innovative technology to the problem – and that’s what World Creativity and Innovation Day is all about.

Solar power is essential for the future

The concept of solar power has been around for centuries, and the world’s first ‘solar collector cell’ was designed in 1767. But inventing the technology and implementing it – especially on a nationwide scale – are very different things.

Today, we understand that solar power is necessary. According to research from Columbia University, an acre of solar panels producing zero-emissions electricity saves between 121 to 138 metric tons of carbon dioxide per year.

Not only is it far more environmentally friendly and sustainable – the construction of solar power generators is more likely to stay on budget and schedule. Scaling up solar power should therefore be a top priority, but today just 3.3% of UK households are generating power using solar.

Construction must lead the way

The construction industry has well documented sustainability challenges. But we also have the opportunity to champion innovation and normalise the use of solar power and other innovative technologies.

What is needed to achieve this? It’s simple: projects need to prioritise the use of equipment that makes the most of cutting-edge technology and pushes us closer to true sustainability – which is exactly what Welfare Hire is dedicated to providing.

solar-powered mobile welfare units

Welfare Hire has always been at the forefront of innovation in our industry. As powerful new technology appears, we pride ourselves on using it to solve important problems for our partners – the most important of which today is sustainability.

Our leading mobile welfare units exemplify the qualities of World Creativity and Innovation day. Not only do they feature a Smart Water system, they use innovative technology to make construction sites more sustainable.

Features include:

Solar and lithium hybrid power

Each unit is fitted with XL solar panels, ensuring that the entire unit can be powered purely using solar power. On top of that, there is a next generation lithium battery that acts as a backup for the mobile welfare unit, and which also recharges from the solar technology. The result is a massive reduction in carbon emissions, noise pollution and running costs.

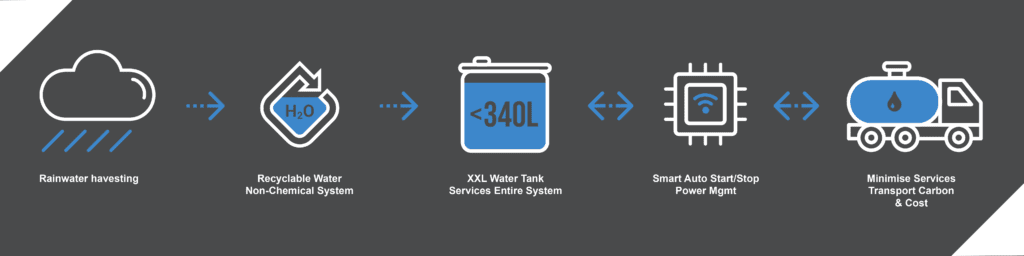

Rainwater harvesting

Helping users reduce water usage and improve their environmental credentials with ease. The toilet system in all of our units is non-chemical, so it can be fed by rainwater. The rainwater harvesting system helps supply an XL water tank that services the entire system – all of which minimises the environmental and financial cost of servicing your mobile welfare unit.

Smart telemetry

Empowering users to monitor and manage their fuel usage, unlocking new levels of efficiency and eliminating downtime. Users can view live and historical volumetric data via a dashboard, to ensure optimal green silent running from the hybrid power system. The result? Fewer servicing trips, which means lower emissions and a big saving for your project.

Evolution is never finished

World Creativity and Innovation Day is meant to celebrate bold steps forward. But it’s also important to remember that this process is never finished. While we are proud of our products, it is essential to our ethos to continue improving them. Not just because it’s what our partners deserve, but because it’s what we love to do.