With chronic labour shortages and declining productivity, UK construction firms need to deliver better employee experience. But research suggests things are trending in the opposite direction.

A recent poll found that 37% of workers feel their employee experience is worse than it was before the pandemic, with 53% feeling less motivated. This puts extra pressure on leaders to find novel solutions to their employees’ problems – one of which is improving on-site facilities.

In this article, we explore three ways our new EcoWC2 towable toilet block solves problems that harm employee experience on construction sites:

1. Increased comfort

Cramped, uncomfortable hygiene facilities are the norm on construction sites. In fact, one study found that 1 in 5 sites fail to meet legal requirements with their welfare facilities. This sends a clear message that employees’ safety and comfort is not a priority.

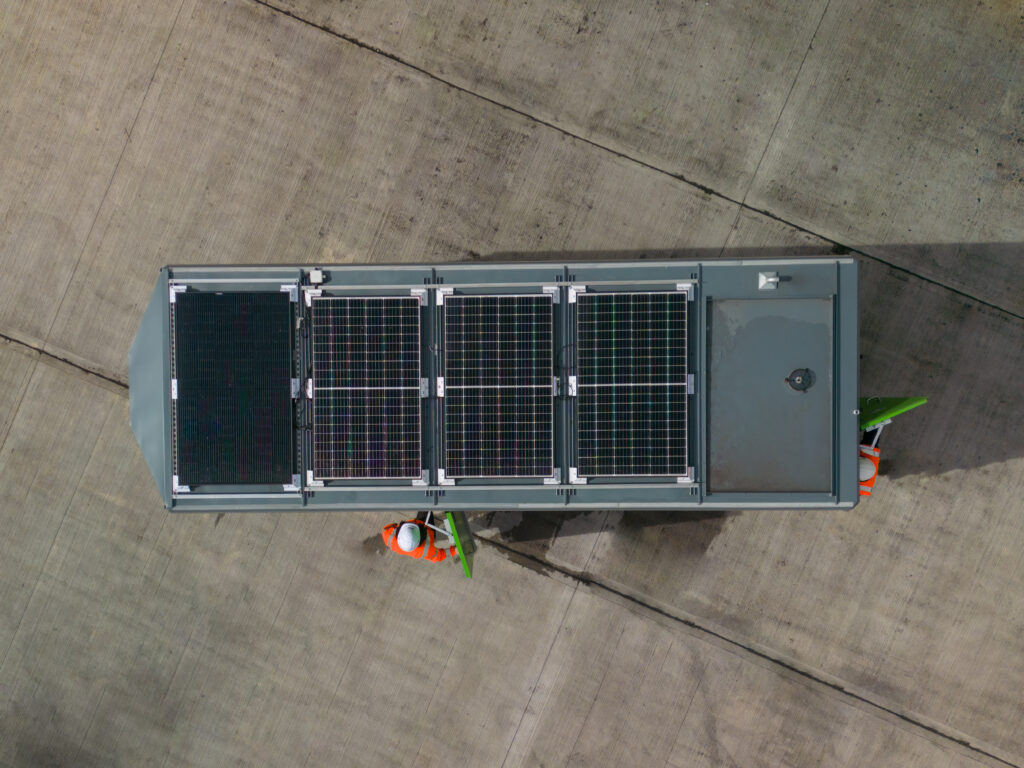

The EcoWC2 reverses this narrative. It provides separate XL, non-chemical, water system wash and changing facilities that not only ensure optimal hygiene, but provide a more comfortable experience for users. From coat hooks and air fresheners to non-slip chequer plate flooring.

2. Easy access and setup

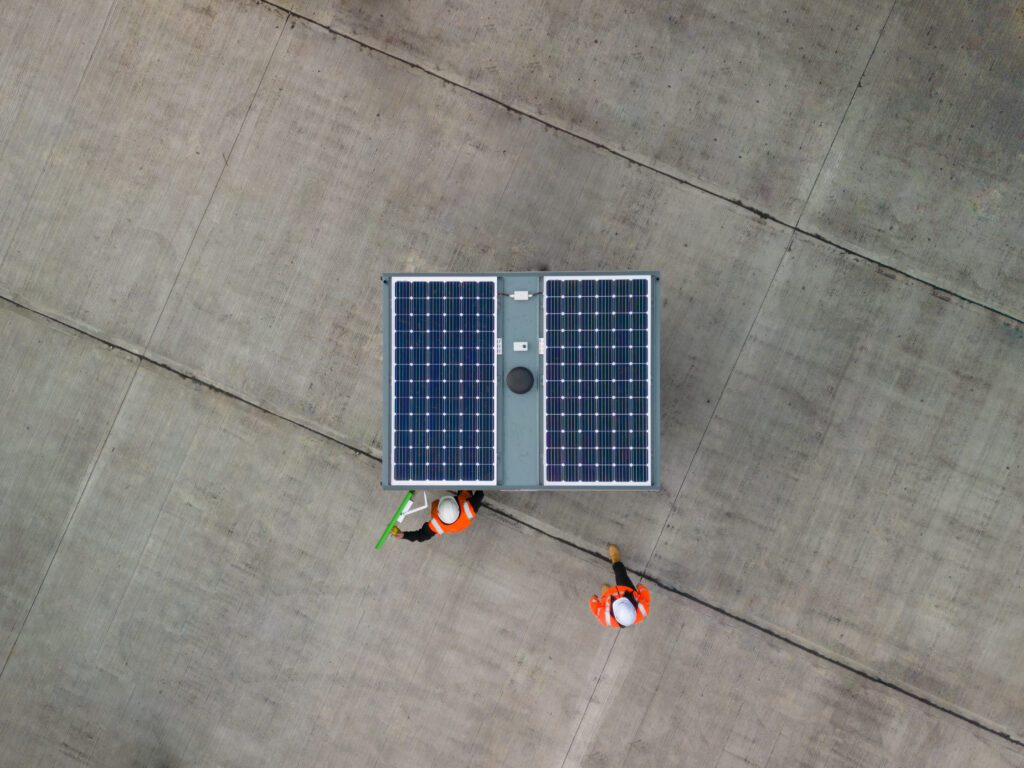

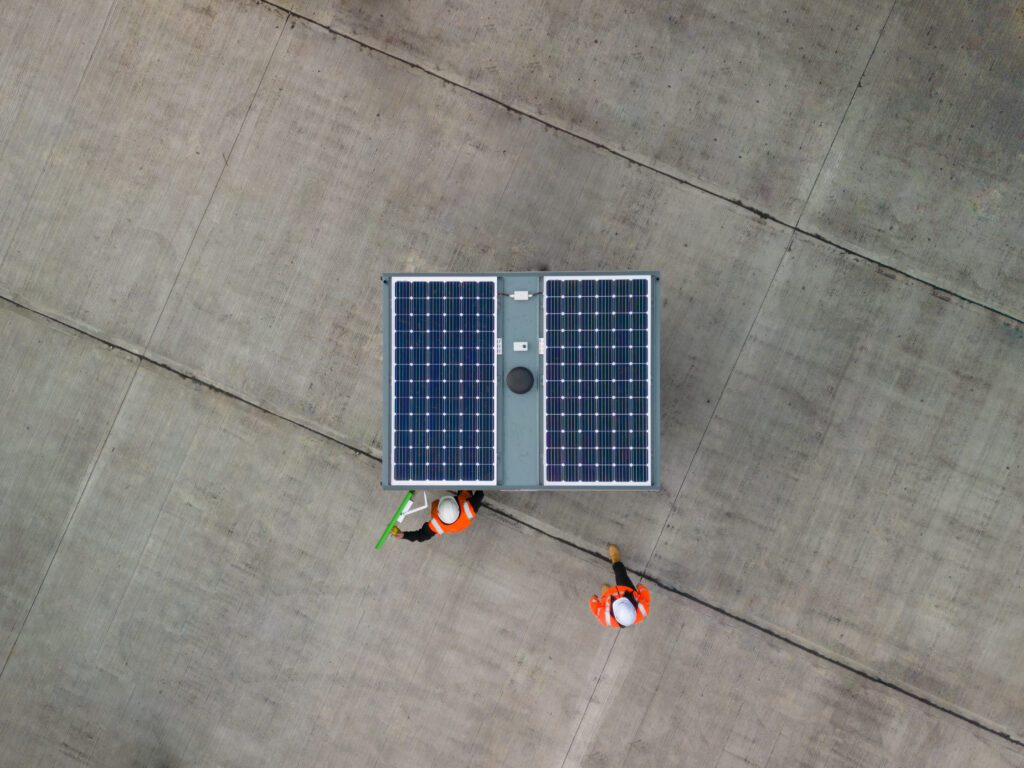

Bringing most toilets onto your site requires Heavy Goods Vehicles or site access plans. This creates additional stress for site managers, but the EcoWC2 removes that stress.

The facilities are easily towable, making access and setup seamless on every construction site. Facilities can be placed wherever will be most convenient for workers, ultimately creating a more positive daily experience.

3. Minimised servicing time

The frequency of toilet service intervals – i.e., how often facilities require emptying of waste and refilling with water – is usually framed as a cost-saving factor. The less often you have to empty and clean the waste tank, the less you spend on things like transport. But there is another element to consider here: access to the facilities.

Even relatively short periods where toilets are unavailable can have a negative impact on your staff, and the EcoWC2 ensures this is not an issue. It minimises service intervals through a combination of XL waste tanks and smart telemetry to monitor tank levels – delivering cost savings, carbon reductions and a better experience for employees.

Small Changes Make a Big Difference to Employees

At Welfare Hire, we believe improved equipment is one of the simplest and most effective ways of improving employee experience. Getting fundamentals like welfare units or on-site WC facilities right can have an outsized impact on everything from your carbon footprint to employee engagement and retention.

Want to learn about our full range of innovative welfare products?