After a decline in project starts this year, experts predict the UK’s construction sector will see a 12% recovery in 2024. This will create huge opportunities for successful firms, but there will also be an increase in competition over contracts.

How can firms remain competitive, and what should they do today to win more contracts in 2024?

In this article, we explore three ways mobile welfare units can help firms in the new year:

1. Focus on ESG

The challenge:

Pressure to decarbonise construction supply chains and create a more sustainable way of working is nothing new. But 2024 will see Environmental, Social and Governance (ESG) scores go from a growing concern to a crucial competitive advantage.

Firms must already show their net zero commitments to bid on contracts worth £5 million or more, and the new year will only see this trend towards ESG-focused tenders grow, especially as the Government seeks to regulate ESG ratings agencies in January and produce more reliable, consistent measurements.

What you can do today:

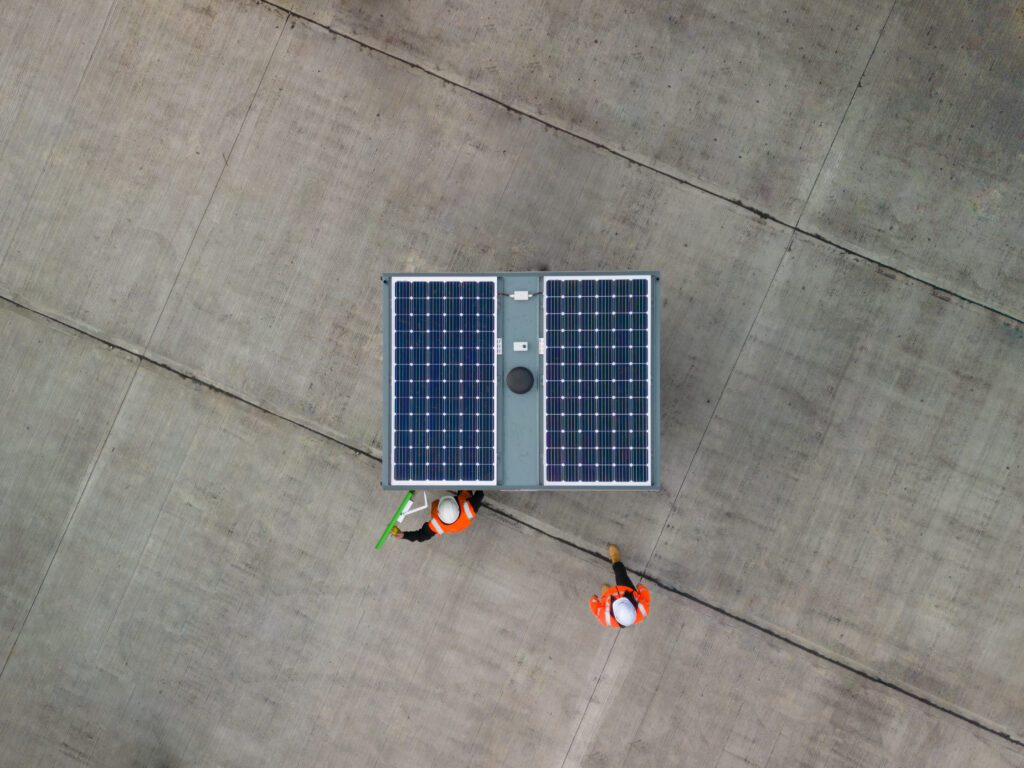

ESG is inherently complex, but factors like adopting eco-friendly mobile welfare units and tower lights can only have a positive impact on your score. The EcoXLi is a perfect example: it runs on 100% solar power and uses next generation lithium battery cells to negate the need for a generator. But it also features a smart telemetry system to guarantee optimal usage of power, as well as rainwater harvesting to minimise water waste.

2. Invest in staff wellbeing

The challenge:

Two factors will converge to make staff wellbeing a priority in 2024: the ongoing mental health crisis in construction and talent shortages. A recent study found that over 50% of construction workers suffer with mental health issues, while 63% of trades are struggling to find new staff in the UK.

As a result, there will be an even greater premium on employee retention. Firms that attract and retain workers will be better equipped to deliver projects on time, and face fewer issues around shortages, absenteeism and low morale.

What you can do today:

There are many factors that influence staff wellbeing, from site safety to schedule flexibility. However, one of the most decisive is the quality, size and comfort of your on-site welfare units.

Welfare Hire’s ECO XLi mobile welfare unit supports employee wellbeing and retention in several ways:

- The XL internal space enables more staff to use units at the same time. This encourages team bonding and ensures important conversations around mental health can be conducted in a safe, comfortable environment.

- Improved non-chemical XL wash facilities improve hygiene for smarter, safer working and cater for more dynamic workforces.

- The investment in higher quality, technologically advanced welfare units signal to employees that you value their wellbeing.

3. Build stronger supplier relations

The challenge:

With a large dip in output and an increase in project delays across 2023, the new year will see many firms racing to make up for lost time. The challenge then will be staying on schedule and keeping costs under control – both of which put firms at the mercy of their volatile supply chains.

The solution is to build more robust relationships with your suppliers, including everything from raw materials to strategic equipment like mobile welfare units. But how can firms achieve this?

What you can do today:

The key is to select suppliers that provide comprehensive support and treat the relationship as a partnership, collaborating to add further value.

At Welfare Hire, we take pride in the strength and durability of our customer relationships. From specialist support and dedicated services to strategic collaboration on how to deploy our mobile welfare units and tower lights most effectively on projects, we offer the kind of reliable, added value service our partners need.

Prepare for 2024 with Welfare Hire

Build a robust partnership with Welfare Hire to improve ESG and employee wellbeing – and support your tendering process in the new year.